Root Cause Analysis and Corrective Action – 2-Part Web Series

Learn More

This two part webinar series will teach attendees how to conduct and document a robust root cause investigation. The tools that will be taught are 5WHYs, Fishbone Diagram, Cause and Effects Matrix, IS/IS NOT and Fault Tree Diagrams. This course will teach attendees how to develop and implement effective corrective and preventive action in order to eliminate the root cause of adverse events, defects or less than desirable present states. Attendees will learn best practices for capturing lessons learned at the end of a project.

Why You Should Attend:

At the heart of every corrective or preventive action, every lean, six sigma and continuous improvement project is one thing – root cause analysis. Root cause analysis is the determination of the root cause (most principal reason) that an event has occurred (or may occur). It is the elimination of root cause through corrective or preventive action which drives ongoing improvement. This course is a must for anyone whose goal is to improve quality and help drive continuous improvement.

Program Schedule:

Module I – (2 Hours)

- Determining Root Cause

- Root Cause Analysis Tools

- Deciding on appropriate corrective or preventive action

- Evaluating root cause assessments

- Evaluating corrective or preventive action

Module II – (2 Hours)

- Conducting and documenting investigations

- Writing effective problem statements

- Communicating effectively

- Report writing and distribution

- The Root Cause Analysis and Corrective Action Process

Who Should Attend:

- Quality Departments

- Product Development Departments

- Production Departments

- Manufacturing Departments

- Engineering Departments

- Operations Departments

- Project and Process Engineers

- Facility Engineers and Managers

- Quality Auditors

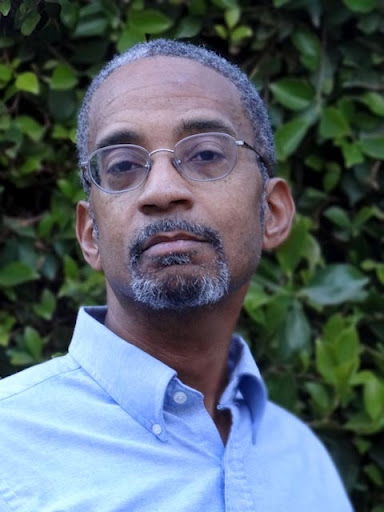

Course Director: LANCE B. COLEMAN

|

|